Department of Mechanical Engineering - Engineering Sciences

Department of Mechanical Engineering

Engine Combustion & Optical Diagnostics LAB (ENCOD)

Engine combustion and optical diagnostics laboratory performs research on the combustion analysis of the internal combustion engine, fuel spray characteristics, alternative energy, after-treatment system, wasted heat recovery system, and the improvement of cooling and lubrication system. Especially, in regards to the increasing interest in the issue of global warming, the ENCOD lab. focuses on improving the fuel economy, the exhaust emission characteristics through alternative energy, and the wasted heat recovery system. Also, the ENCOD lab. performs a simulation in parallel experiments using 1-D simulation codes such as AMESim, Wave, and Flowmaster.

Virtual Dynamics LAB

Virtual Dynamics Laboratory develops a numerical analysis for multi-body mechanical systems through the analysis of mechanical systems, statics, dynamics, design sensitivities, eigenvalues and flexible bodies. The numerical methods can analyze variable mechanical systems and assist in design optimization.

We focus our studies in the field of dynamic behavior analysis. The exsisting software can be used for the linear or non-linear system analysis and he multi-body system analysis. The field applies inself in the machinery industry; the evaluation of system performance and the analysis of different machines and its structure, vibration, fatigue and design. We handle problems in regards to high speed rotation, small mass and high stiffness, flexible body(a lot of DOF) and real time analysis using the relative coordinates, sequential equations and non-linear flexible body elements. This can be applied automobiles, railroad cars, caterpillar vehicles, electronic equipments, vital dynamics, and more.

Automatic Design LAB (ADL)

Our research interests are classified into five different fields, including but not limited to structural optimization, robust design, multidisciplinary optimization, axiomatic design, and crashworthiness. New methodologies for structural optimization have been developed. In the field of robust design, the Automatic Design Laboratory (ADL) has developed robust design theories and has successfully applied them to industrial products for many years. ADL has developed a multidisciplinary optimization method where a large system is decomposed into small systems and each small system is independently designed. Axiomatic design is studied for conceptual design. ADL has carried out the crash analysis of an automobile, an armored vehicle, an airbag, and an automobile seat as an industrial project.

Vibration LAB

The vibration laboratory investigates the causes behind the noise and vibration that occurs in various structures, such as industrial machineries and automobiles, and carry out researches to solve these problems. The structures that are to be studied have complex vibrations due to elastic deformation and rigid body motions, and have dynamic phenomena depending on the structural conditions and operating environments. Therefore, this laboratory constructs a dynamic model properly, based on experiments, theories, and parallel simulations to ensure dynamic stabilities and vibration reductions.

Micro Electro Mechanical System(MEMS)

The mission of the Micro Electro Mechanical System Laboratory (MEMS Lab.) is to design and invent the micromachines. We are dedicated to addressing the design of electro mechanical systems on the micro scale and the fabrication of the micro machine, based on nano/micro machining technology. We research the microbial/microfluidic fuel cells, the source of power of the next generation, and the bio Lab-on-a-Chip for medical diagnostic devices.

Advanced Materials & Innovative Design LAB

The major research areas are divided into two categories: Printed Electronics utilizing Micro/Nano Direct Printing Technology spotlighted as the emerging new technology and Innovative Design with Advanced Materials. We are investigating both the basic and applied technology related to two areas. We are also interested in generating new and creative research topics through a cross-link between the two fields.

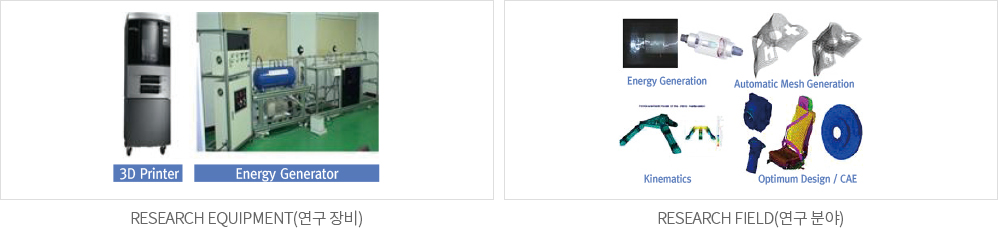

Intelligent Computer Integrated Design LAB

At the Intelligent Computer Integrated Design (ICID) LAB, mechanical systems including industrial plants and their associating parts can be designed and manufactured with systematic development of the design and analysis process by integrating existing knowledge and automating the entire procedure. Current researches includes the development of Automatic Mesh Generation for FEM analysis in shape modeling, kinematics, and energy development for the next generation's energy. For Energy development, our lab has performed a joint research with Keldysh in Russia and MIT in the United States. We are part of committee that founded a national project dedicated to developing a Hydrogen Reserve and Distribution system and its utilization with Jeolla-do, other related companies and universities. In addition, a joint research plan is under development for Power Plants and their parts with major global companies in Korea.

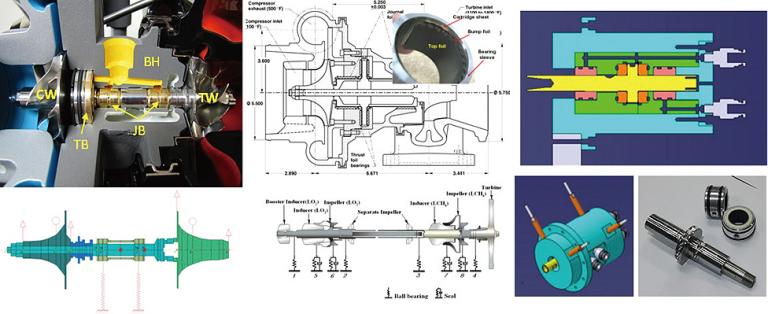

Turbomachinery LAB

The Turbomachinery Laboratory at Hanyang University conducts fundamental and advanced research on the performance of modern turbomachinery. We perform comprehensive measurements and predictions of the rotordynamic characteristics of turbomachinery. We also focus on experiments for validating computational fluid film models for the prediction of the static and dynamics forced performance of fluid film bearings, seals, and dampers.

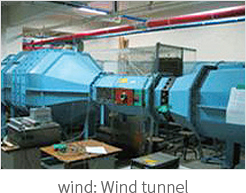

Fluid Engineering LAB

At the Fluid Engineering Lab at Hanyang University, we conduct research on environmental fluid dynamics, alternative energy, fluid flow measurement method, and fluid simulation for industrial application & MEMS. In contribution to the general public's increasing interest in environmental issues concern and alternative energy, we have recently started to focus on hydrogen energy, ultra-clean energy plants, and waste water treatment. In connection with those topics, we also analyze several fluid flow problems by using the CFD(Computational Fluid Dynamics) code, FLUENT. Experimental equipments of the Fluid Engineering laboratory consist of two wind tunnels and the flow measurement systems. One of the wind tunnel is an open-loop type subsonic wind tunnel and the other is a closed-loop type subsonic wind tunnel. Experimental equipments including flow measurements are the turbine flow meter and the KANOMAX hot wire current meter.

Applied Computational Design & Fluid Dynamics LAB

Applied Computational Design & Fluid Dynamics (ACD&FD) Laboratory tries to overcome the disadvantages of the experimental system such as space limitations and, high costs involved in manufacturing and time through the mechanical engineering simulation. Moreover, the laboratory struggles to achieve the academic and technical development in the fluid dynamics field via joint project/-technical transfer with our own know-how.

Computational Hybrid Analysis of Materials Processing LAB

Computational Hybrid Analysis of Materials Processing(CHAMP) Laboratory. has been focused on deformation, structure analysis and process design of conventional metals, aluminum(Al) alloys, and light-weight metals including Titanium(Ti), Zirconium( Zr), and Magnesium(Mg) alloys based on the theory of computational mechanics and plasticity. They characterize and develop constitutive equations and deformation models adapted to various kinds of applied materials with respect to the deformation path, strain rate, temperature, and more. We have analyzed hybrid materials such as multi-layers, multi-material mix, and claddings in terms of hardening, failure, and interface to correlate fabrication methods with computer simulations. Collaboration network does not only include POSCO, Samsung, Hyundai heavy industries, and LG Electronics, but also cover national labs such as KIMS, KITECH, KAERI, KIMM, and more.)

Energy and Environmental Engineering LAB

As environmental and energy issues have greatly intensified, the development of energy-efficient, cost-effective and yet environmentally-friendly industrial processes has become a necessity. At the Energy and Environmental Engineering Laboratory, the analysis, design, and the optimization of process systems are conducted theoretically and experimentally in order to improve their performance, efficiency, and environmentally-friendly features. In particular, our main focus is on the following research topic: (i) thermal- and membrane-based desalination and ultrapure water production for industrial processes, (ii) membrane- and adsorbent-based humidification/dehumidification, (iii) carbon dioxide capture and sequestration, (iv) solar energy applications, (v) mathematical modeling and optimization of thermal system and (vi) reduction of harmful gas emission, etc.

Precision & Measurement Engineering LAB

The ‘Precision & Measurement Engineering Lab. (PME)’ was opened in 1995 under Prof. Cho Nam-gyoo. Recent trend of high accumulation and precision has required Micro/Nano technology in the Mechanical Engineering Industry. Therefore, the measurement technology is also required in a Micro/Nano scale. Corresponding to the industrial needs, this lab focuses on the development of the measurement system, surface metrology, precision positioning technology, sensor development, 3D vision measurement technology, and data processing technology.

Materials Design and Reliability LAB

Our laboratory investigates mechanical performances and fatigue strengths of structural materials and composites through experiments, computer simulation and theory. Several experimental techniques are employed such as defect analysis using a lock-in thermography and 3D full field strain analysis by digital image correlation apparatus. Those studies applies to reliability life and safety analysis for the mechanical structures of automobiles, energy industries and clinical medicine. The present topics display very high cycle fatigue behaviors of bearing and spring steels, low cycle fatigue strengths of stainless steels and cast irons, electro-chemical degradation characteristics of rubber hoses for cooling the automobile engine as well as polymerization shrinkage stress analysis of dental composite resins.

Nano Intelligent Manufacturing LAB

The Nano Intelligent Manufacturing Laboratory(NIML) at Hanyang University performs research on nano and intelligent manufacturing. Our research area is composed of machining process modeling, machining process automation, and AE sensor monitoring. Also, we develop sensor fusion and precision manufacturing, nano manufacturing through the use of lasers and AFM(Atomic Force Microscope) study of burr formation and the, MR polishing system.

Thermal Engineering & Materials Processing (TEMP) LAB

The Thermal Engineering & Materials Processing (TEMP) laboratory. has carried out the theoretical and experimental investigations to analyze and optimize the performance and efficiency of industrial processes related to energy, water and environmental issues. The major research areas of the TEMP lab. are: (i) theoretical modeling and optimization of thermal system in consideration of heat and mass transfer and chemical reactions, (ii) carbon dioxide capture and sequestration, (iii) purification process for biogas and engine exhaust gas and (iv) fresh- and ultrapure-water production processes using thermal-, electrical,-and membrane-based desalination technologies, amd more.